FATIGUE TESTING LAB

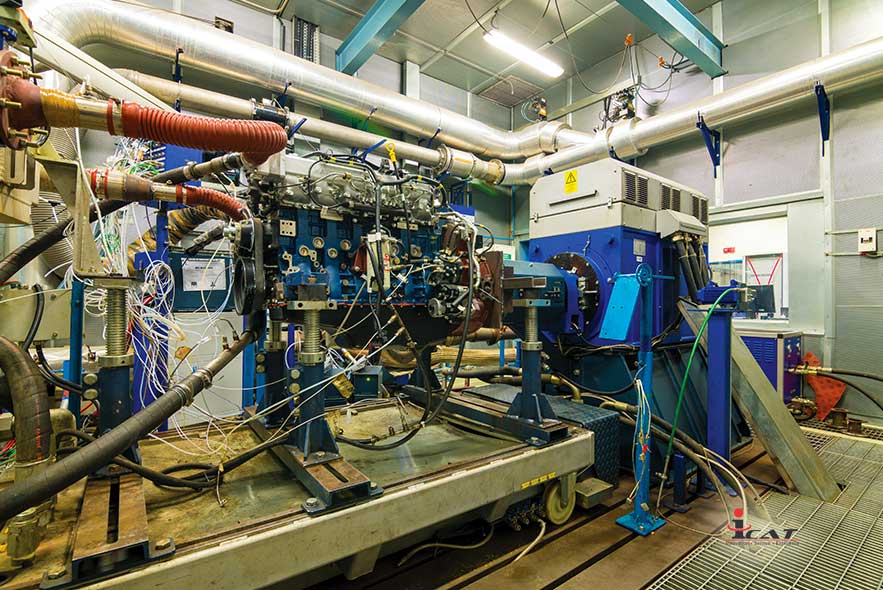

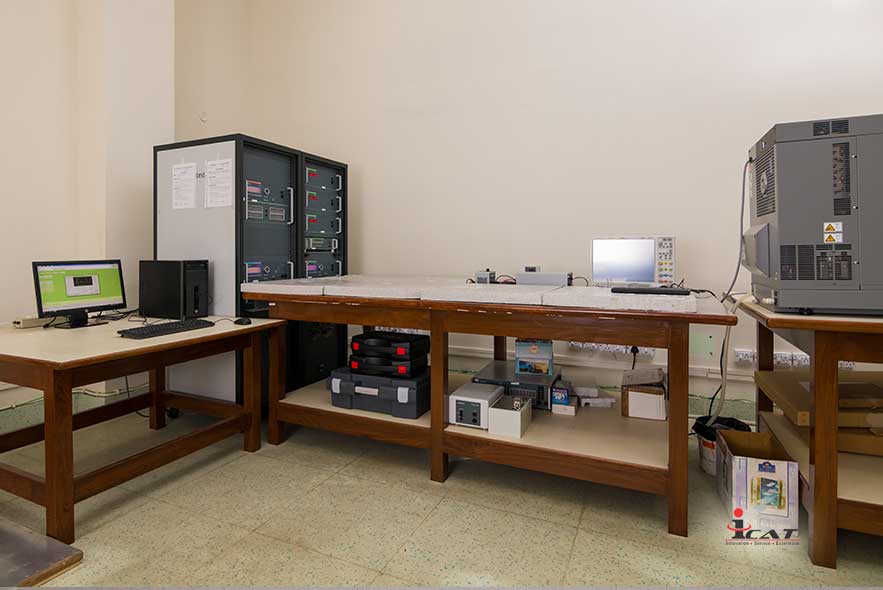

Fatigue test lab at ICAT is state of the art testing facility to support automakers and suppliers for development and validation of various structural components, its sub-assemblies, 2-wheelers, 3- wheelers, 4-wheelers, Tractors, CEVs etc as below:

- Single & Multi-axis Structural Durability using servo-hydraulic actuators from 1 kN to 1000 kN

- Simulation Testing with Road Load Data on 4-, 6-poster & MAST.

- Vibration testing with environmental conditions.

- Complete DVP testing for Pass car, CEV, Truck & Buses, Special Ability Vehicle for Both ICE and EV.

Capabilities

-

-

- Structural Durability test – Single Axis/ Biaxial/ Tri axial and Multi Axial testing.

- Vibration Testing as per JIS D1601 under NABL Accreditation using Shaker & MAST.

- OECD accreditation of ROPS & FOPS.

- ROPS testing as per IS/ISO 3471: 2008 & FOPS testing as per IS/ISO 3449: 2005

- RUPD as per IS 14812: 2005 & SUPD as per IS 14682: 2004

- Endurance testing of Leaf Spring assemblies for Automobiles as per IS 1135:1995 under NABL Accreditation using Servo-Hydraulic Actuators.

- Structural Durability by simulating the acquired Road Load Data.

- Complete capability for Road load data acquisition with Wheel force transducer

- 4-Poster as per IS 15901: 2010 for bumper fitment evaluation under NABL Accreditation.

- Developed the facility for Durability testing of tractor steering system inside the climatic chamber.

- Structural Durability testing of Tele

- handler Chassis for off road vehicle.

- Suspension Spring Durability for Railway.