- VEHICLE EVALUATION LABORATORY

- TEST TRACKS

- Automotive Transmission Engine Test Cell

- TYRE TEST LAB

- PASSIVE SAFETY LAB

- PHOTOMETRY LAB

- NVH LAB

- INFOTRONICS LAB

- FATIGUE TESTING LAB

- ELECTRICAL AND ELECTRONICS LAB

- EMC LAB

- CAD/CAE LAB

- ENVIRONMENTAL TESTING

- ADAC Facility

- COMPONENT TEST LAB

- EMC LAB

- ENGINE TEST CELL

- EMISSION LAB

ENVIRONMENTAL TESTING

VEHICLE EVALUATION LABORATORY

Vehicle Evaluation Lab (VEL) undertakes road worthiness trials for all categories of vehicles ranging from two wheelers to heavy commercial vehicles, trailers, construction equipment vehicles and agricultural tractors. VEL undertakes key test like Maximum speed, Acceleration, Fuel Consumption, Endurance and durability running, Coast down test, Brake performance, ABS test, Noise Vibration & Harshness, Tyre noise test, rolling resistance, Wet Grip & Rolling Sound Emissions and performance requirements of new pneumatic tyres, in accordance with CMV Rules, European Regulations, FMVSS.

TEST TRACKS

The Vehicle Test Tracks (VTT) supports in homologation, research and development activities in the area of vehicle dynamics. To facilitate all dynamic tests, Vehicle test tracks at ICAT have following test tracks: – OVAL Track ABS Track Hill Track Comfort Track ISO Track Water Track Dynamic Track

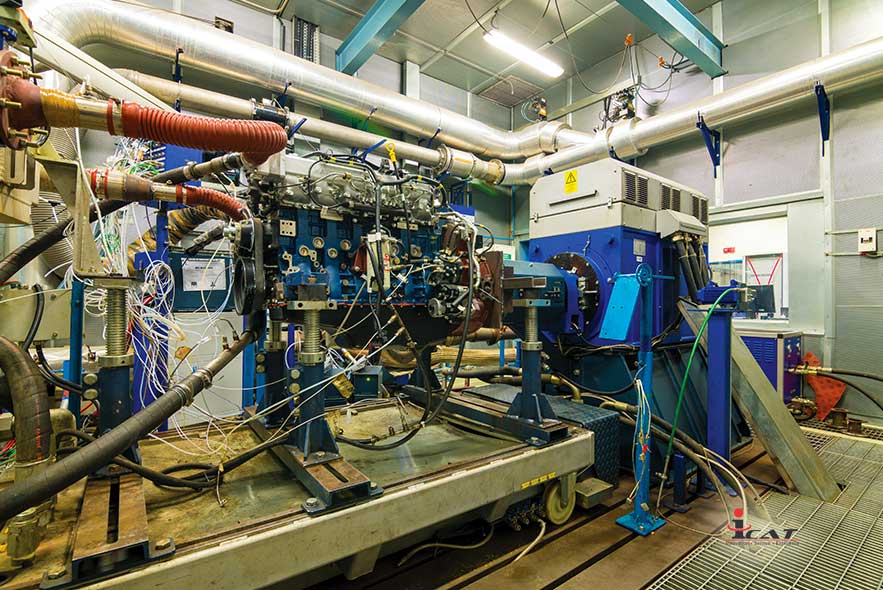

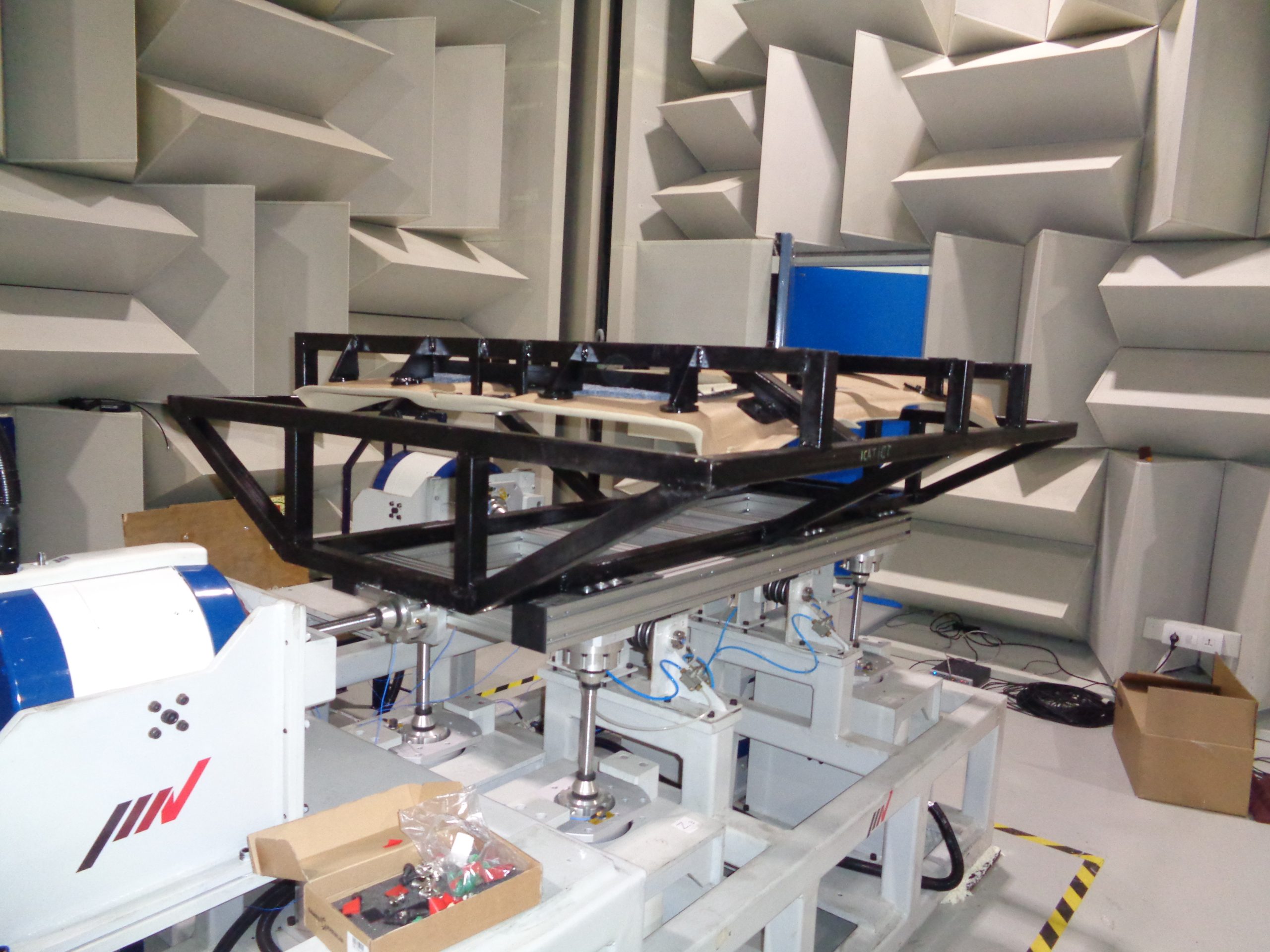

Automotive Transmission Engine Test Cell

Automotive Transmission Engine Test Cell established in view to perform test on ‘Front and Rear Wheel Drive’ vehicles for ‘Noise, Vibration & Harshness’ purpose. The lab will also capable to test all drive line components along with various transmission units with respect to Noise, Vibration & Mechanical Performance. Broadly comprises Hemi-anechoic chamber (Sound Absorption Wedges), Vibration source identification devices (Microphone array) and Data Acquisition System for latter stage processing of vibration signals.

TYRE TEST LAB

Pneumatic Tyres play crucial role in the Safety of automobiles. Understanding the Performance of tyre and tyre mechanics is critical in determining their influence on the ride, handling and safety of two wheelers, three wheelers, cars & commercial vehicles. ICAT’s Tyre Test Lab (TTL) is NABL Accredited and approved by Bureau of Indian Standards (BIS). TTL is providing services related to Type Approval & Conformity of Production of Tyres as per AIS:037 (CMVR). Apart from this, the tyre test lab is providing services of Tyre Testing of samples submitted by Bureau of Indian Standards (BIS), Indian & Foreign Tyre Manufacturers

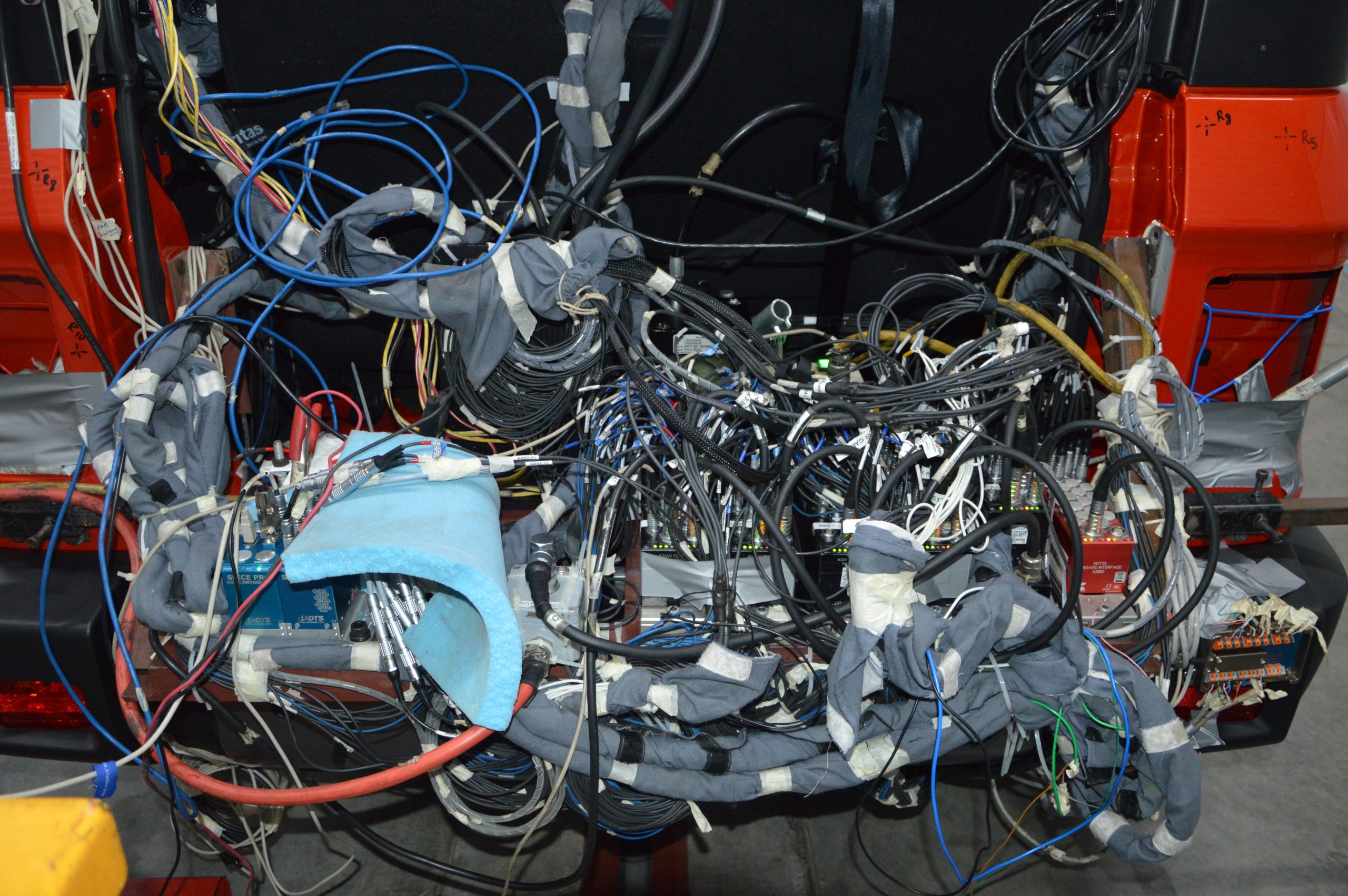

PASSIVE SAFETY LAB

ICAT’s Passive Safety Lab (PSL) is capable of performing Crash Tests, Pedestrian Protection Tests & Sled Tests as per various Indian, International and NCAP regulations (including Bharat NCAP). The Passive Safety Lab of ICAT will play a vital role to support automotive industry for their upcoming needs of Crash Testing (developmental & certification) owing to Notification released by Ministry of Road Transport & Highways (MoRTH), Govt. of India for the implementation of crash norms in India w.e.f. 1st Oct’2017 (new models).

PHOTOMETRY LAB

Photometry lab at ICAT has the state-of-the-art infrastructure to cater to the requirements of both Automotive and non-automotive lighting components. The lab is equipped with latest facilities capable of testing high end products like intelligent lighting systems, PWM based LED luminaries, lights with high flashing rates, Special purpose warning lamps, Aviation lights (Taxi way, Edge lamps, Approach lights, Centre line lamps), Street Lights, Flood Lights, Indoor lights, medical lights etc. The photometry lab at ICAT is accredited as per ISO 17025 by National Accreditation Board for Testing and Calibration Laboratories (NABL) and American Association for Laboratory Accreditation (A2LA) and BIS

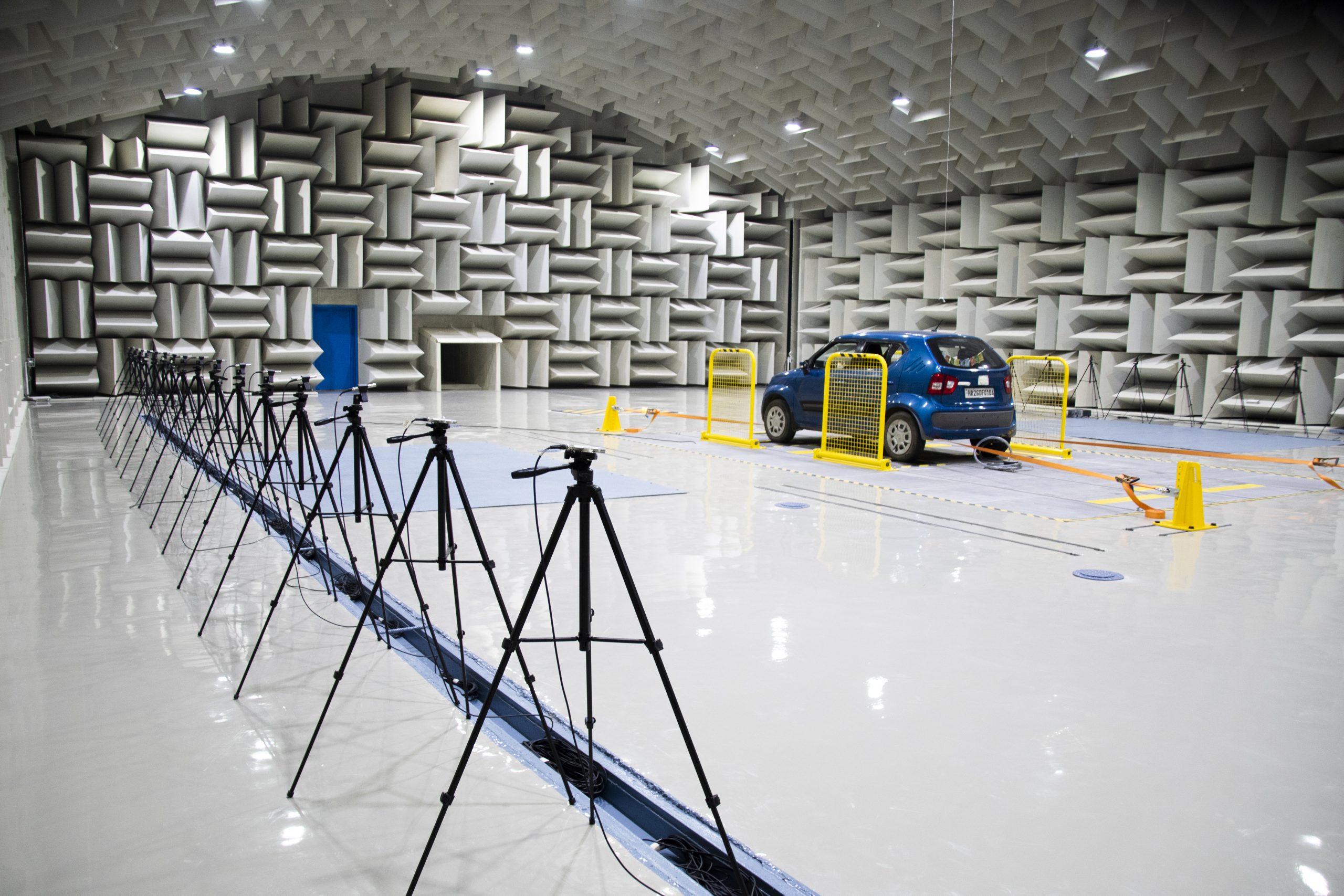

NVH LAB

ICAT’s NVH Lab is equipped with the best-in-class infrastructure, instrumentation, software and highly capable team. ICAT’s NVH team is committed to provide services and solutions to our partners in automotive and non-automotive sectors for their NVH benchmarking, target-setting and validation requirements. Additionally, the team also assists genset industry in the development, validation and certification of their domestic and export models. COMPETITIVE ADVANTAGE Dedicated Test Facilities for EPAC, 2W, 3W, 4W, LCV, HCV for trials on vehicle and component level Trained testing team with proven capability catering to test requirements of leading OEM’s Troubleshooting, Root cause analysis

INFOTRONICS LAB

Considering the ever increasing electronics in vehicles; Infotronics lab focusses at development work in the field of ECU development in major core areas: Testing and validation of existing ECU control functions. Design and development of new ECU control algorithms. Plant model development for ECU close loop validation and Engine hardware simulation. Virtual Calibration. SIL/MIL/HIL Simulation.

FATIGUE TESTING LAB

Fatigue test lab at ICAT is state of the art testing facility to support automakers and suppliers for development and validation of various structural components, its sub-assemblies, 2-wheelers, 3- wheelers, 4-wheelers, Tractors, CEVs etc as below: Single & Multi-axis Structural Durability using servo-hydraulic actuators from 1 kN to 1000 kN Simulation Testing with Road Load Data on 4-, 6-poster & MAST. Vibration testing with environmental conditions. Complete DVP testing for Pass car, CEV, Truck & Buses, Special Ability Vehicle for Both ICE and EV. Capabilities Structural Durability test – Single Axis/ Biaxial/ Tri axial and Multi Axial testing.

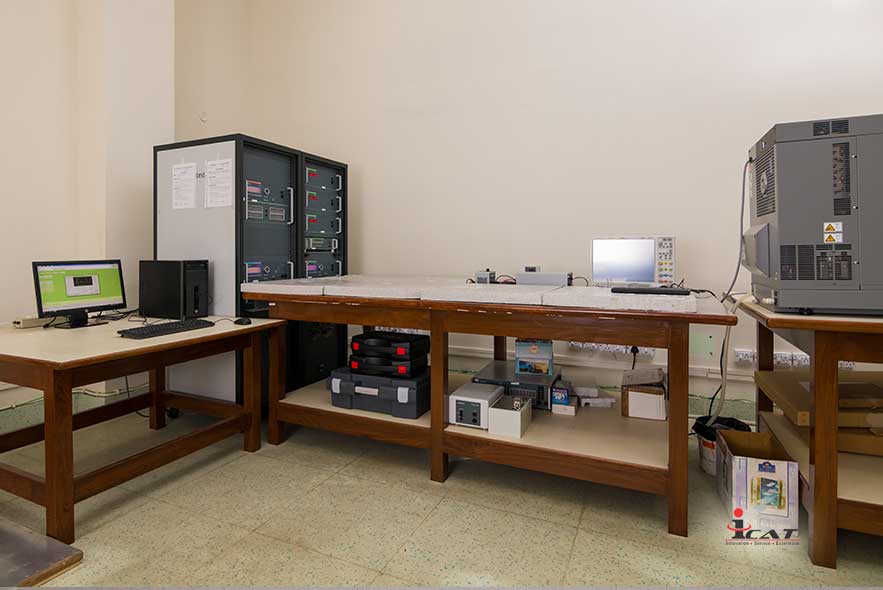

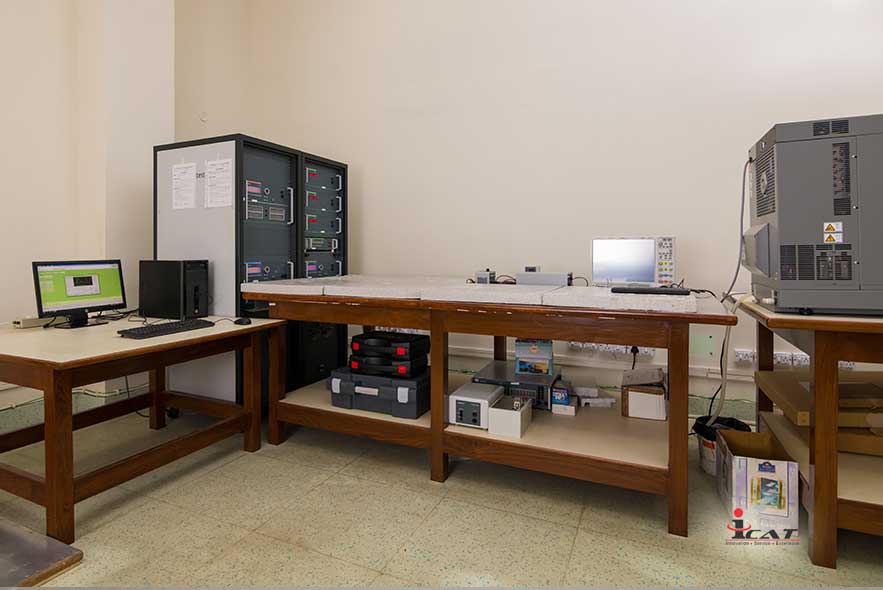

ELECTRICAL AND ELECTRONICS LAB

EEL at ICAT incepted in 2013, is amongst the best maintained and managed Electrical and Electronics laboratory compliance with ISO 17025 and accredited by NABL & A2LA for a diverse scope. The Devices we test include VAS, SLD, CNG-LPG Components, Horns, Batteries, Motor, Wiring Harness, White Goods, IT Equipment/Audio Video devices, Medical Devices, ITS components, EVSE, Subassemblies related to CASE (Connectivity, Autonomous, Sharing/Subscription and Electrification) Technology etc. EEL is also capable of doing core projects on HEV/EV. We also have Deep Penetration in Various panels for formulation of national test standards under BIS as well as AIS. We are always

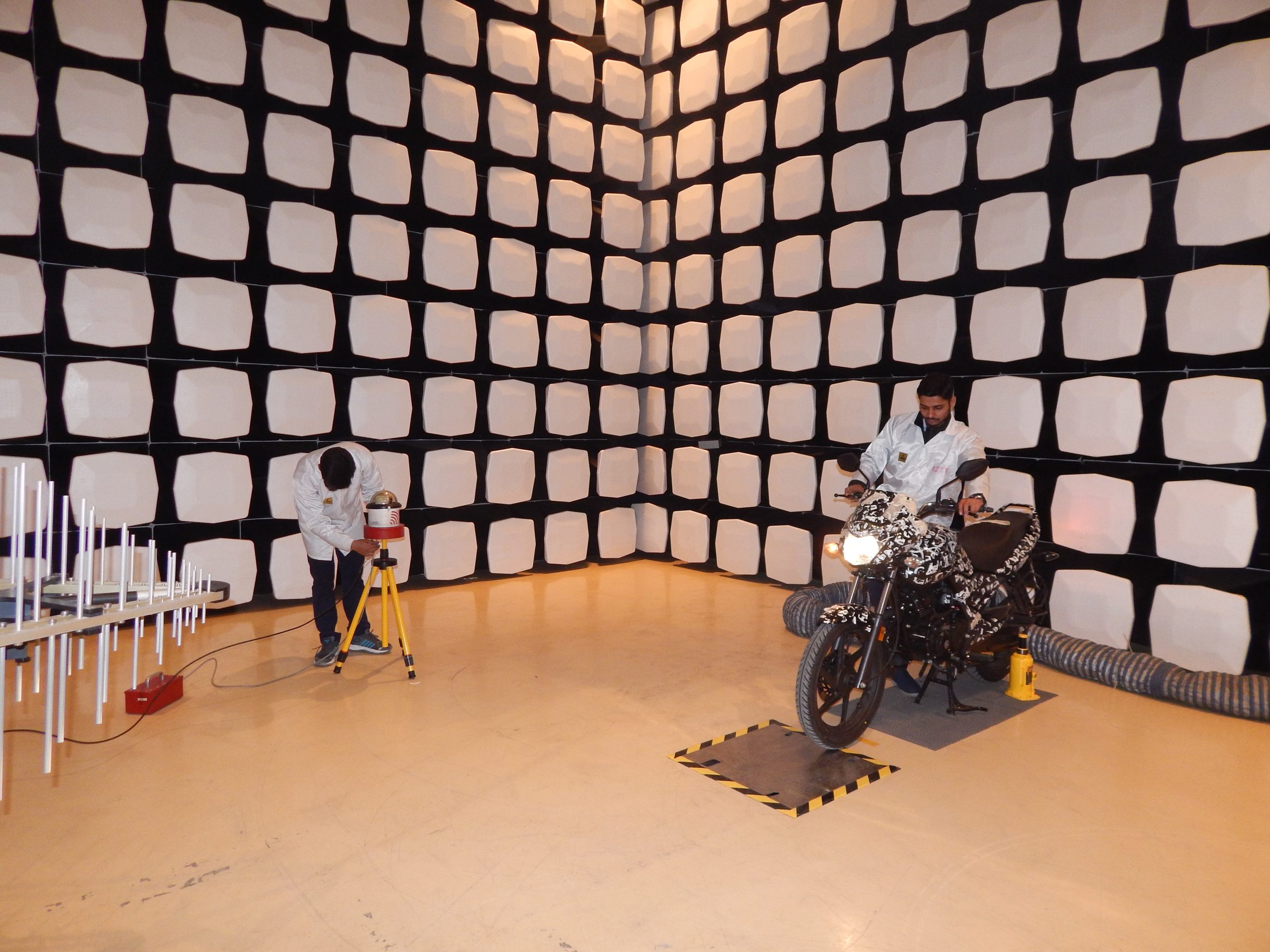

EMC LAB

EMC lab at ICAT is state-of-the-art facility which can cater to the automotive as well as non –automotive requirements. There are 02 anechoic chambers with adequate instrumentation to support the EMC test requirements: Pre-compliance as well as Compliance tests for electrical/electronic subassemblies, all Vehicles Categories (2W, 3W, 4W, Buses, Trucks, E-rickshaw, E-Cart, Tractors, Trailers, etc.), including Conventional Fuel Vehicles, Electric Vehicles, Hybrid Vehicles, Heavy Commercial Vehicles, Agricultural Vehicles, Unmanned Aerial Vehicles, Construction Equipment Vehicles, other devices related to Gensets, Information Technology, Household, Multimedia, Medical, Industrial, Railway, Defence, Drone, Lighting, Electric Vehicle Supply Equipment (EVSE), Consumer electronics, Wireless devices, Telecomm devices,

CAD/CAE LAB

ICAT is having Computer Aided Design (CAD) and Computer Aided Engineering (CAE) facilities which have come up as the key product development techniques for all manufacturers. Engineering design and analysis plays an important role in the product development. Considering the global competition in the automotive market, the product development needs to be accurate, cost effective and time bounded. We at CAE are offering customized solution from vehicle concept to certification through simulation.

EMISSION LAB

The vehicle test cell at ICAT can do regulatory and development mass emission testing for 2-wheelers, 3- wheelers and 4-wheelers. The capabilities include testing for regulatory requirements as per Indian and International regulations upto BS VI norms. The lab is also capable of conducting Real World Driving emissions using Portable Emission Measurement System (PEMS). The Climatic Vehicle Test Cell (CVTC) can conduct mass emission tests and cold startability/performance tests for passenger vehicles and off-road vehicles at extreme temperatures and solar load.

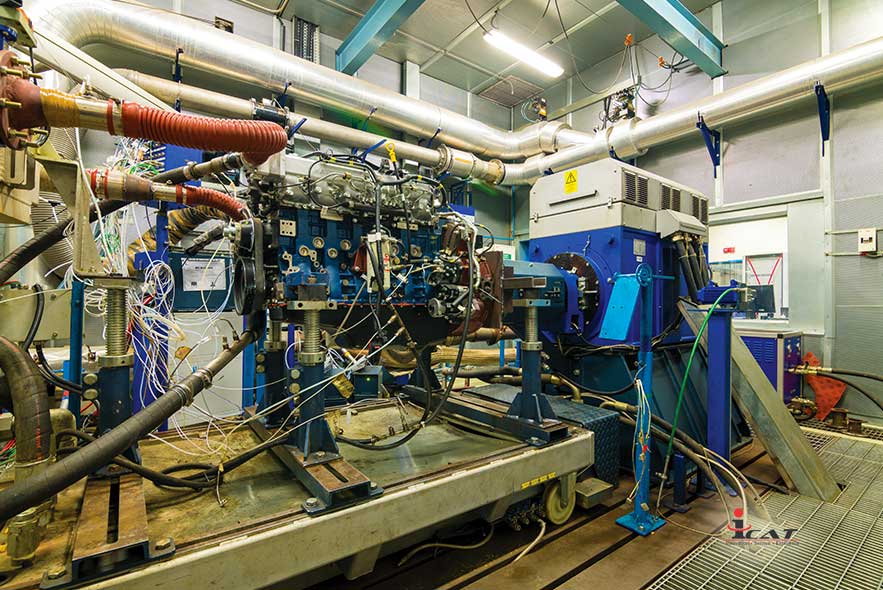

ENGINE TEST CELL

At ICAT, Engine and E-motor Test Laboratory is capable of performing Certification as well as Developmental trials for Medium & Heavy-Duty Vehicle’s engine with GVW above 3.5ton. The lab offers dual stream emission testing of engines along with high altitude simulation capabilities. The EV test labs are also equipped with battery emulator for testing electric motors up to 300 kW. The domain of testing with respect to the application of engine includes- BSVI Automotive, Power Tiller – TREM III, Tractor – TREM IIIA, Stage IV, V and CEV – BSIII, BSIV, BSV and Genset as per National & International Standards.

EMC LAB

EMC lab at ICAT is state-of-the-art facility which can cater to the automotive as well as non –automotive requirements. There are 02 anechoic chambers with adequate instrumentation to support the EMC test requirements: Pre-compliance as well as Compliance tests for electrical/electronic subassemblies, all Vehicles Categories (2W, 3W, 4W, Buses, Trucks, E-rickshaw, E-Cart, Tractors, Trailers, etc.), including Conventional Fuel Vehicles, Electric Vehicles, Hybrid Vehicles, Heavy Commercial Vehicles, Agricultural Vehicles, Unmanned Aerial Vehicles, Construction Equipment Vehicles, other devices related to Gensets, Information Technology, Household, Multimedia, Medical, Industrial, Railway, Defence, Drone, Lighting, Electric Vehicle Supply Equipment (EVSE), Consumer electronics, Wireless devices, Telecomm devices,

COMPONENT TEST LAB

Component Test Lab (CTL) provides services pertaining to Certification, Homologation of Automotive Components & Sub-assemblies as per Central Motor Vehicle Rules (CMVR). The certification services include Type Approval & Conformity of Production (CoP) of safety components identified in AIS: 037. Apart from certification, CTL supports OEMs and components manufactures of the automotive industry for various developmental DV/PV Testing of components as per customers & OEMs standards. CTL also conducts type testing of Wheel Rims & Safety Glasses for BIS Licenses as per Quality Control Order (QCOs). CTL has state of art test facilities for conducting various tests on DVP programs

ADAC Facility

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.